This article is about the application of li-ion cells in EV or energy storage and study li-ion cell temperature wrt discharge rate vs time. The discharge rate is defined as the ratio of average discharge current and ampere hour capacity. As we know the li-ion cells has less moving parts compared to conventional IC engines which makes the design and manufacturing of the electric vehicles easier. The discharge rate of li-ion cell is far more superior than a conventional lead acid battery. With advantages on the li-ion cells there are factors also to consider while designing the battery module such as chemistry for application such as NMC, LFP and so on, insulation, structural design and thermal management.

Abstract

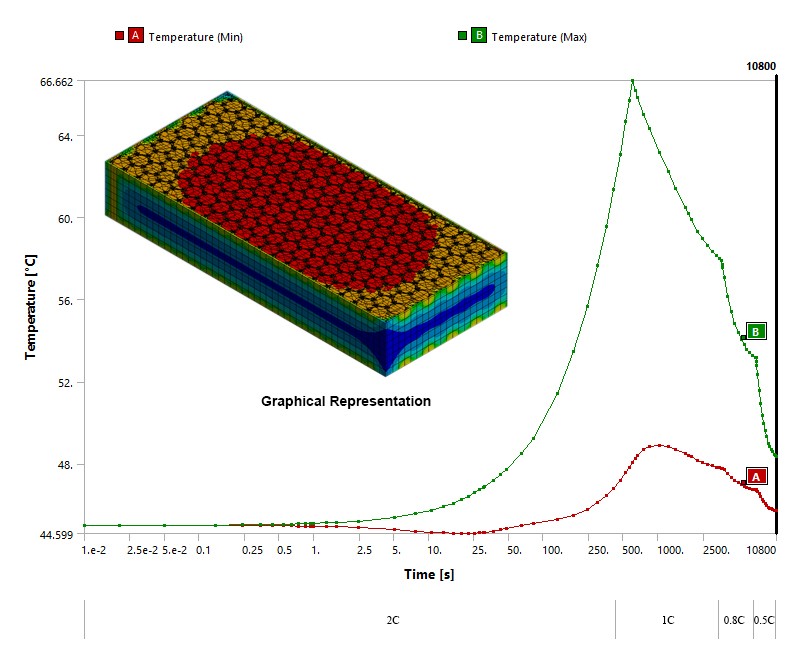

In some cases the design of battery module is done considering 2C/1C discharge in longer time, it might work in cases where the ambient temperature is 25°C but the problem is when the ambient temperature is greater than 45°C. The BMSprotects the battery against the over temperature where the cutoff threshold is preset, this affects the performance when temperature rises rapidly. The below study shows the graph for temperature with respect to time and discharge rate.

Study

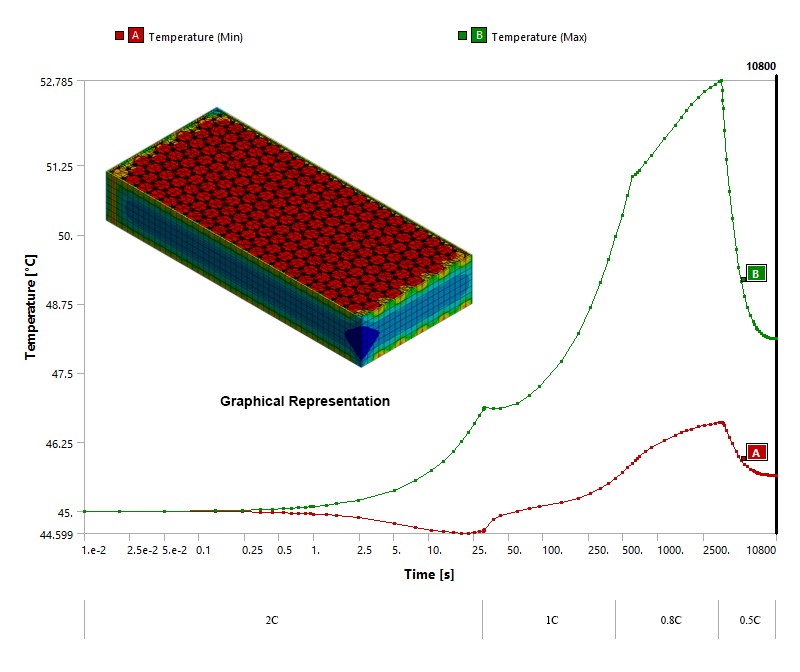

The following study uses 21700 5Ah cylindrical cell. As per BAK N21700CG-50 cell has charge temperature range of 0°C to 45°C and discharge temperature range of -20°C to 60°C. So lets simulate 21700 5Ah cell with ambient temperature of 45°C, convention and radiation to ambient and discharge rate as per the chart below.

The above graph has a boundary inputs of 2C discharge for 10 minutes, 1C for 50 minutes, 0.8C for an hour and 0.5C for an hour. The temperature in mid region rises to the peak when battery is at 2C and considerably high at 1C. This in EV there is a thermistor in the battery which sends feedback to motor controller and automatically reduces the discharge rate, this causes a sluggish throttle which does negatively impact.

The above graph has a boundary inputs of 2C discharge for 30s, 1C for 9 minutes 30 seconds, 0.8C for 50 minutes and 0.5C for 2 hours. The temperature is within the discharge limits. This gives a user a steady throttle which improvise the reliability of the vehicle.

Conclusion

Thermal management is a important criteria in battery pack design. So, the decision of passive cooling or active cooling should be calculated and not assumed. With passive cooling high discharge rate should be for less time and use low discharge rates.

LFP cells are much safer due to their inherent stability and reduced risk of thermal runaway compared to traditional lithium-ion batteries.

With active cooling higher discharge rates can be used for longer time. A trick to use passive cooling with longer high discharge rate is to use PCM but it has its own advantage and disadvantages.